涂布机的工作原理、磨损原因及修复方法

时间:2025-04-27 来源:/ 发布人:昌盛机械

一、涂布机简介

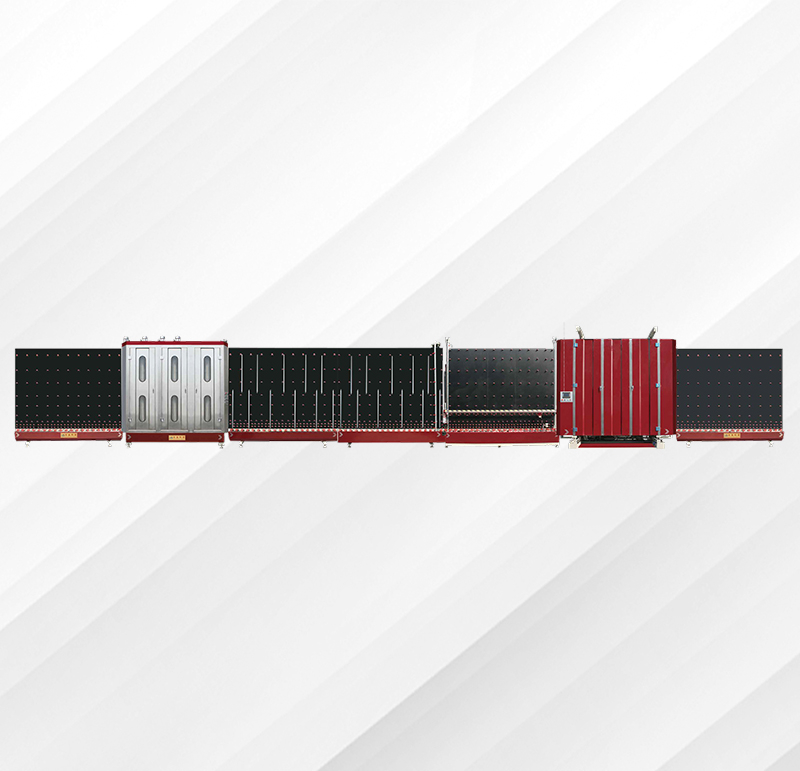

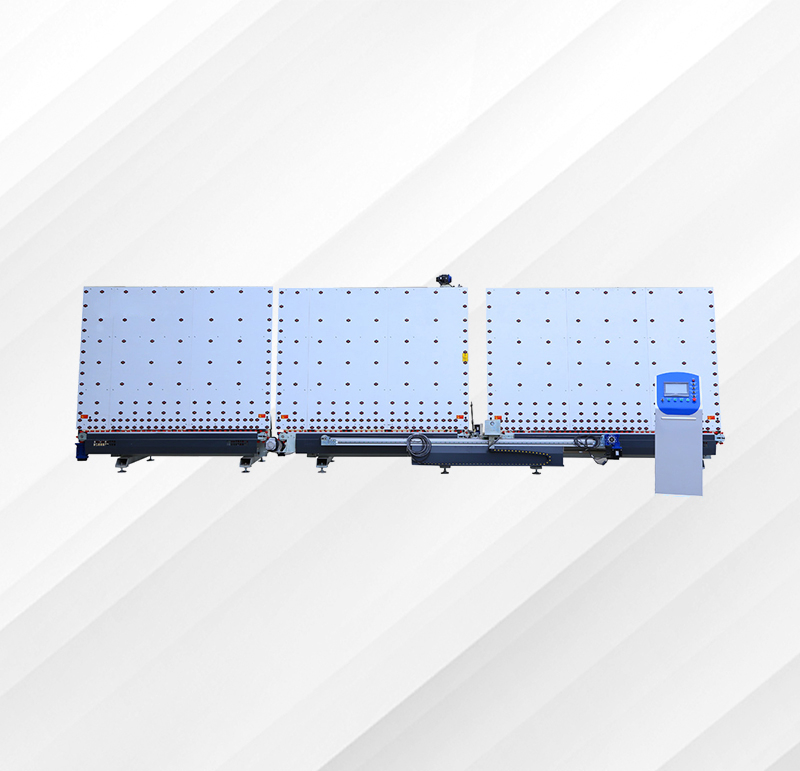

1、 Introduction to Coating Machine

涂布机是一种用于在基材表面均匀涂覆涂料或涂层的机械设备,广泛应用于印刷、纺织、造纸、电子、医药、食品等行业。其核心结构通常包括旋转轴、滚筒、刮刀、喷枪等组件,通过不同的涂布方式(如刷涂、刮涂、辊涂或喷涂)将涂料均匀施加到基材上。

Coating machine is a mechanical equipment used for uniformly coating coatings or coatings on the surface of substrates, widely used in industries such as printing, textile, papermaking, electronics, medicine, and food. Its core structure usually includes components such as a rotating shaft, drum, scraper, spray gun, etc., which evenly apply the coating to the substrate through different coating methods (such as brushing, scraping, roller coating, or spraying).

二、涂布机磨损的主要原因

2、 The main reasons for the wear of coating machines

长期运行后,涂布机关键部件可能因以下原因发生磨损:

After long-term operation, key components of the coating machine may experience wear and tear due to the following reasons:

摩擦磨损:运动部件(如滚筒、轴承)间的持续摩擦导致表面损耗。

Friction and wear: Continuous friction between moving parts such as rollers and bearings leads to surface wear.

腐蚀与氧化:环境中的化学物质或湿气引发金属部件锈蚀。

Corrosion and oxidation: Chemical substances or moisture in the environment can cause corrosion of metal components.

应力疲劳:长期承受机械应力,导致材料疲劳、变形或开裂。

Stress fatigue: Long term exposure to mechanical stress leading to material fatigue, deformation, or cracking.

材料缺陷:部件本身存在气孔、裂纹等缺陷,加速磨损。

Material defects: The component itself has defects such as pores and cracks, which accelerate wear.

高温影响:工作温度过高可能导致热膨胀或热疲劳磨损。

High temperature impact: Excessive working temperature may lead to thermal expansion or thermal fatigue wear.

润滑不良:润滑剂不足或劣质润滑剂加剧摩擦损耗。

Poor lubrication: Insufficient or inferior lubricants exacerbate friction losses.

三、涂布机磨损的修复方法

3、 Repair methods for coating machine wear

针对不同磨损情况,可采取以下修复措施:

For different wear conditions, the following repair measures can be taken:

表面处理

Surface Treatment

抛光/研磨:轻微磨损可通过打磨恢复表面平整度。

Polishing/Grinding: Slight wear can be restored to surface smoothness through grinding.

电镀/喷涂:对腐蚀或氧化部位进行电镀(如镀铬)或喷涂耐磨涂层。

Electroplating/Spraying: Electroplating (such as chrome plating) or spraying wear-resistant coatings on corroded or oxidized areas.

更换易损件

Replace vulnerable parts

定期检查并更换磨损严重的部件(如刮刀、轴承、密封圈)。

Regularly inspect and replace severely worn components such as scrapers, bearings, and seals.

补焊修复

Repair welding

对裂纹或局部损伤采用焊接修补(适用于金属部件)。

Welding repair is used for cracks or local damage (applicable to metal components).

调整工艺参数

Adjust process parameters

优化涂布速度、压力及温度,减少异常磨损。

Optimize coating speed, pressure, and temperature to reduce abnormal wear.

加强润滑维护

Strengthen lubrication and maintenance

选用高性能润滑剂,并定期补充或更换。

Choose high-performance lubricants and regularly replenish or replace them.

升级材质

Upgrade Material

替换为更高耐磨性材料(如陶瓷涂层、合金钢等)。

Replace with higher wear-resistant materials (such as ceramic coatings, alloy steel, etc.).

四、预防磨损的建议

4、 Suggestions for preventing wear and tear

定期清洁设备,避免杂质加速磨损。

Regularly clean the equipment to avoid impurities accelerating wear and tear.

严格按操作规范使用,避免超负荷运行。

Strictly follow the operating procedures to avoid overloading.

建立维护计划,关键部件定期检查与保养。

Establish a maintenance plan and regularly inspect and maintain key components.

若磨损问题复杂或无法自行处理,建议联系专业维修人员或设备制造商进行诊断与修复。

If the wear issue is complex or cannot be resolved by oneself, it is recommended to contact professional maintenance personnel or equipment manufacturers for diagnosis and repair.

本文由玻璃涂布机设备友情奉献.更多有关的知识请点击:http://www.china-greatflooring.com我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is a friendly contribution from glass coating machine equipment For more information, please click: http://www.china-greatflooring.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 全自动丁基胶涂布机操作注意事项:细节决定品质与效率 2025/05/27

- 双组份打胶机:解码胶水混合后的固化时间控制艺术 2025/05/26

- 卧式丁基胶涂布机传动系统维护要点解析 2025/05/20

- 中空玻璃加工必备8大设备详解 2025/05/19

- 全自动铝条折弯机在工作中有什么优势? 2025/05/16

- 全自动丁基胶涂布机在工业领域做出来什么优化? 2025/05/14

- 智能升级!全自动封胶线设备实现高精度、高效率密封作业 2025/05/12

- 双组份打胶机定制流程是什么样的? 2025/05/09

- 中空玻璃丁基胶涂布机在运行的过程中可能会出现的问题? 2025/05/07

- 全自动铝条折弯机先进的技术有什么? 2025/05/06

当前位置:

当前位置:

产品分类Product categories

产品分类Product categories

联系我们Contact us

联系我们Contact us